As industries demand faster, safer, and more precise inspection methods, non-contact NDE encoders have become the benchmark for modern non-destructive examination. Explore our NDE services to see how evoARC technology is leading this transformation.

Understanding the NDE Landscape

The Importance of Non-Destructive Examination

Non-destructive examination (NDE) enables the evaluation of materials and systems without compromising their integrity. It’s critical for industries like aerospace, energy, and infrastructure.

From ultrasonic testing to MIC detection, NDE ensures operational safety while minimizing downtime and structural risks.

Challenges in Traditional Encoder Systems

- Physical contact-based mechanisms are prone to wear and tear

- Slippage and misalignment lead to inaccurate data capture

- Frequent recalibration and complex setup slow down operations

- Wheeled encoders are only practical at encoding travel along cylindrical assets, not circumferential position

These issues slow down inspections and introduce uncertainties in corrosion monitoring and defect localization.

Introducing evoARC Technology

What Sets evoARC Apart

evoARC technology offers a non-contact indexing solution for high-precision single-axis data acquisition on cylindrical assets. Visit our accessories section to see compatible upgrades.

Core Benefits

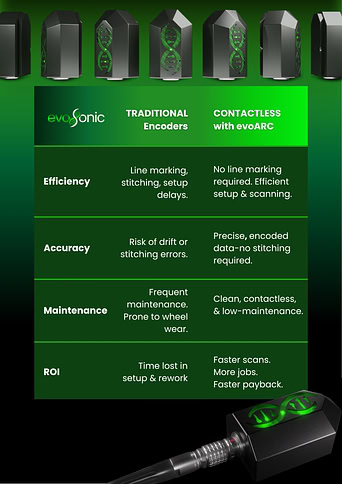

No Line Marking Required – Reduces setup time and eliminates manual tracking errors.

High-Resolution Tracking – Achieve accuracy down to 0.013mm (0.0005″).

Non-Contact Design – No wheels or drag; zero surface damage or contamination.

LED Position Indicators – Visual feedback at 12, 3, 6, and 9 o’clock for intuitive alignment.

Tool-Free Mounting – Installs in seconds with a rugged, screw-less setup.

IP67 & MIL-STD-810G Rated – Built for harsh environments and field conditions.

These features dramatically improve field inspections using ultrasonic testing and other advanced NDE methods.

Compatible with Existing Systems

evoARC is designed to work with a wide range of NDE tools, especially where legacy encoders fail. Learn about ultrasonic testing tools that benefit from evoARC.

Contactless NDE Encoders: The Technical Edge

How They Work

Contactless NDE encoders use optical and magnetic sensing to track motion with high precision, even on curved or coated surfaces. This eliminates the need for surface preparation.

These encoders integrate seamlessly with scanners for corrosion monitoring, pipe inspections, and surface profiling.

Technical Comparison Table

| Feature | Contactless Encoder | Traditional Encoder |

| Surface Contact | None | Required |

| Setup Time | Minimal | High |

| Maintenance | Low | Frequent |

| Slippage | None | Common |

| Surface Compatibility | All types | Limited |

| Dual-axis Support | Yes | Rare |

Applications of evoARC Encoders

MIC Detection in Pipelines

Microbiologically influenced corrosion (MIC) is a growing concern in oil, gas, and marine sectors. evoARC’s high-resolution encoders ensure reliable tracking even on complex surfaces.

- Detect MIC signatures earlier

- Avoid pipeline shutdowns

- Enhance inspection repeatability

Check out MIC detection tools

The evoARC in Aerospace & Structural Testing

evoARC ensures every scan captures precise positional integrity—even on curved or coated surfaces—making it especially effective for aerospace structures, composite panels, and mission-critical infrastructure. Its non-contact design and LED-guided alignment reduce human error and deliver high-resolution data with minimal setup.

Dive into the specifications of evoARC : https://evosonic.ai/

Corrosion Monitoring in Harsh Environments

In offshore or industrial plants, surface debris and curvature create challenges. evoARC’s contactless system overcomes:

- Surface inconsistencies

- Hazardous conditions

- Harsh weather

See corrosion monitoring solutions: https://evosonic.ai/

Why evoARC Is a Trusted Choice for Modern NDE

evoARC isn’t just a contactless encoder—it’s a field-ready precision tool engineered to simplify inspections without sacrificing accuracy. Its non-contact design eliminates the need for line marking or drag wheels.

With real-time LED position indicators at 12, 3, 6, and 9 o’clock, operators gain intuitive alignment guidance for faster setups and consistent data. Its high-resolution tracking (down to 0.013mm) makes it ideal for critical inspections where precision is non-negotiable.

Tested to MIL-STD-810G standards and IP67-rated for dust and water resistance, evoARC is trusted in harsh environments—from offshore rigs to remote pipeline corridors—delivering dependable performance across diverse industries and applications.

Real-World Case Study: Oil & Gas Facility

Challenge: Frequent encoder failures on corroded pipelines.

Solution: Replacing with evoARC contactless encoders.

Results:

- 37% improvement in inspection time

- 62% fewer encoder errors

- 95% accuracy in MIC detection

Tips for Implementing evoARC Technology

1. Evaluate Current Encoder Limitations

Pinpoint the bottlenecks in your current inspection workflow caused by traditional encoders. Leverage non-destructive examination (NDE) services to benchmark performance and identify areas for improvement.

2. Choose Compatible Scanner Systems

Use evoARC-compatible scanners and connectors. The accessories page lists options.

3. Train Staff for Digital-First Inspections

Operators should understand how to use frictionless motion encoders and interpret the cleaner data sets.

4. Combine with Smart Data Logging Tools

Pair evoARC encoders with AI-driven data logging for real-time insights. Explore the latest blog on smart NDE.

5. Use in Varied Environmental Conditions

Test evoARC in dry or wet conditions, and on horizontal or angled surfaces. Its flexible mounting and maneuverability make it adaptable across a range of NDE applications—just avoid fully vertical positions where gravity-based guidance is essential.

Infographic: Contactless Encoders vs Traditional Methods

The Future Outlook

Industry Shift Toward Smart Inspection Tools

As industries embrace AI and smart sensor technology, advanced encoders like evoARC are becoming essential infrastructure. Real-time, high-precision inspection with minimal error is no longer a goal—it’s the new standard.

Role in Predictive Maintenance

With better data precision, predictive maintenance becomes proactive. Engineers can intervene before failures occur.

Built for Technicians, Not Just Engineers

evoARC bridges the gap between advanced inspection tools and everyday usability. Its intuitive LED-guided alignment, zero-line marking, and tool-free mounting make it easy for technicians of all experience levels to get reliable results—without specialized training or complex setup

Unlocking NDE Potential with evoARC

The advent of contactless NDE encoders has revolutionized how inspections are performed. With evoARC technology, technician gain speed, safety, and precision across diverse industries.

Whether you’re dealing with MIC, corrosion, or complex composites, evoARC provides an edge. Explore our inspection tools and accessories and see the future of NDE.

FAQs

What else is supplied with the evoARC?

The evoARC is supplied with everything you need to get to work: A Flexoform™ mount,16.4′ (5m) cable, Splitter & cable. All supplied in a Nanuk 915 hard case.

Which scanners is evoARC compatible with?

The evoARC is designed to integrate seamlessly with third-party scanners, including systems like the Evident FlexoFormTM. It supports any PAUT acquisition system using Lemo 1K.316 and Quadrature Encoding—so you can upgrade your existing tools without investing in new hardware.

How does evoARC improve inspection productivity?

evoARC significantly reduces setup time, improves scan accuracy, and eliminates common causes of rework. Users have reported up to 4x faster inspection coverage, especially in complex environments like offshore rope access or large-diameter piping.

Is evoARC durable enough for harsh field conditions?

Yes. evoARC is built to MIL-STD-810G standards, meaning it’s engineered for rugged use in extreme conditions. Electronics are encased in resin, and it’s been tested to IP67. It’s a non-contact encoder, so there should be minimal wear and tear, and no maintenance is required.